Introduction

In today’s process industries, fast and reliable access to operational data is critical. Operators in the control room are tasked with keeping process under control by monitoring multiple information streams to efficiently and effectively make accurate mission and time-critical decisions. When problems occur, Operators need immediate and reliable access to operational data to allow them to react quickly and get processes back under control. By visualizing data in a trend, operational data from different types of equipment can be monitored in real time to troubleshoot equipment, display equipment performance and trend equipment issues.

In their deep-water operational platforms, Shell have benefitted from using Yokogawa’s AutoTrend application with improved performance to deliver control room Operators with real time and long-term operational trends that are critical to operations. With the ability to call up trends within seconds and being able to add pens from Distributed Control Systems (DCS) faceplates, they can monitor different types of equipment and react to changes in the process.

The Importance of Trending Process Data

Huge volumes of data pass through control rooms which can be overwhelming. It’s one thing to present Operators with all this information, but it’s another to make sure it’s processed, analysed, and readily available when called upon. Data trending is critical to many operational processes and used to monitor different types of equipment either in real-time, or to compare information historically over time.

By trending data in real time, it can play a significant role in daily operations by enabling Operators to monitor different pieces of equipment at the same time and to troubleshoot plant upsets or changes to conditions. Many DCS vendors offer native data trending functionality, but it falls outside of the main focus when it comes to the navigation and presentation of long-term historical data together with real time data. Operators need to call up trends from a DCS faceplate and add additional pens for comparison over long periods of time to monitor the process more effectively.

Data Trending with AutoTrend

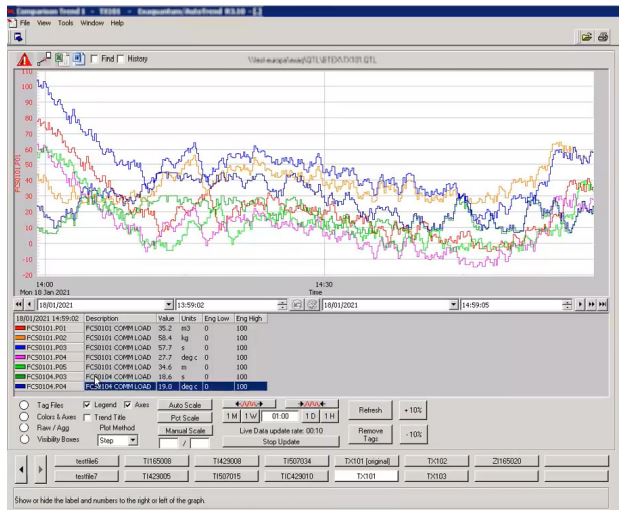

AutoTrend from Yokogawa, provides enhanced trending capabilities for the Exaquantum process historian, enabling users to create and display system-wide, real time, and historical trend information directly from a DCS console. Operators can open pre-configured trends of Exaquantum process data, offering more convenience when compared to native trend controls. With easy-to-use display manipulation, direct trend controls and one-click switching between trends, it provides an intuitive and effective user interface to navigate information quickly and react to process changes in real time.

Fast Access to Data

For operations, having the capability to quickly trend process data is critical to ensure processes remain under control. Operators and Engineers can react to any changes to the process very quickly or troubleshoot and diagnose equipment performance immediately, for example when tuning control valves or monitoring well unloads. Therefore, fast access to trend data is critical for daily operations, providing Operators with up-to-date production information as it happens.

Recently, AutoTrend has boosted its performance in collaboration with Shell as part of the long-term partnership, product lifecycle management and continuous improvement plan. Helping to ensure users have continued fast and reliable access to data, and to call up trends in a matter of seconds from a DCS faceplate. The impact of these operational improvements in AutoTrend are already being realized at Shell’s deep-water platforms.

AutoTrend Performance Improvement

In the latest release of AutoTrend (R3.30) performance has been improved, with trend documents that now load in a matter of seconds when called-up from the DCS faceplate. This can improve the daily operations with fast and reliable access to process trends, offering enhanced trending capabilities compared to native DCS trends.

Operators can quickly view real time process trends to monitor processes and react to any changes during operations. Using pre-defined trend settings, they can also compare repeated process issues very quickly to identify and resolve situations that have a direct impact. It is also very easy to relate data trends with alarm and events, allowing operators to quickly identify relationships between process and alarm data for more informed decision making.

AutoTrend also provides access to long-term historical data in Exaquantum. Providing users with rapid access to years of historical data that can be called up from a DCS console and added to a trend for performance comparison or to understand and visualise any changes to equipment performance over time.

AutoTrend enhancements provide an improved user experience and continues to provide an effective interface for configuring and managing trend information and reports. With fast trend loading, Operators are provided with rapid access to data trends and information to be able to make informed decisions quickly and effectively to improve daily operations.