Exaquantum is one of the most comprehensive Plant Information Management Systems (PIMS) available for process industries. Exaquantum can acquire data from all facets of a process and transform that data into easily usable, high-value, widely distributed information.

The data then becomes an integral part of the set of tools used by the business in vital decision-making processes.

Exaquantum overview

Exaquantum is Yokogawa’s plant historian suite that provides a central database from which information can be extracted and presented to users throughout the organisation, enabling them to achieve safe, reliable and optimal plant operations. Exaquantum acquires data from all facets of a process and transforms that data into easily usable, high-value, widely distributed information that enables the smooth running and optimisation of process operations.

- Easy business-wide information distribution

- Plant data is enhanced and used throughout the business

- Data can be accessed from multiple Process Control Systems

- Provision of long-term history

- Event-triggered processing of data into business information

- Time-resolved event history

- An integrated platform

- Exaquantum runs on the Microsoft Windows platform, using industry standard technologies

Value of Exaquantum

Exaquantum solutions enable continuous improvements in production environments to provide agility and flexibility, asset optimisation, quality improvements, whilst ensuring safe and secure operations. It seamlessly integrates and aligns with Yokogawa and third party DCSs, safety systems, SCADA systems and PLCs.

Exaquantum is the business intelligent gateway between the operational Process Control System (PCS) and the business Enterprise Resource Planning (ERP) system. It uses the latest, proven, Microsoft based open technology sets, designed to have low administration costs, and be robust to future IT trends such as Big Data, IIoT and cloud deployment.

Enhancement to Exaquantum R3.60 (July 2025)

In Release R3.60, Exaquantum has been enhanced in the following areas:

- Performance

- OPC UA Alarms & Conditions client support

- OPC UA DA/HDA Server Write feature support

- Cloud Deployment

- Power BI support

- Yokogawa and Microsoft Environments support

The demand for Cloud-based installations in the process industry is growing. Exaquantum, Yokogawa’s plant historian, provides a platform for transforming process data into valuable business information. Expanding its reach with cloud deployment, on-premise or using a combination of both, Exaquantum powers improvements at every level across the enterprise.

Exaquantum is one of the most comprehensive Plant Information Management Systems (PIMS) available for process industries. Exaquantum can acquire data from all facets of a process and transform that data into easily usable, high-value, widely distributed information.

Exaquantum Videos

| Graphics Conversion from Centum VP to Exaquantum | |

| A concise step-by-step guide on how to import CENTUM VP graphics into Exaquantum Explorer | Part 1

Part 2 |

| Introduction to Calculations | |

| Learn about tags and calculations which can be performed in Exaquantum, including advanced calculations. | Part 1

Part 2 |

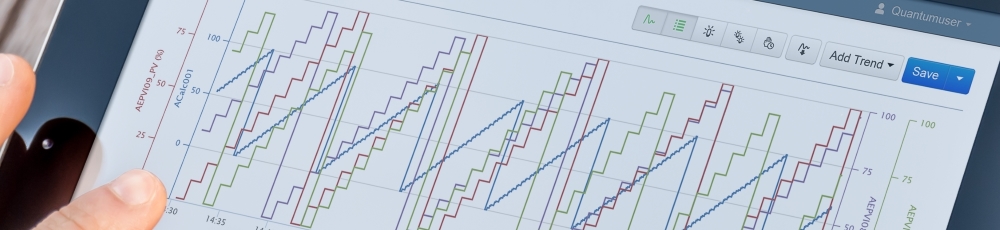

| Introduction to Web Trends | |

| A basic introduction to the Exaquantum Web Trends, covering different features of the tool. | Watch Video |

| Troubleshooting OPC | |

| A step-by-step guide on troubleshooting an OPC DA connection using a variety of useful tools in Exaquantum | Watch Video |

| Configure IIS for Exaquantum Web | |

| An introductory guide on how to install IIS by adding the Web Server Role to Windows 2008 R2. | Watch Video |

| Getting Registry Information from OPC Servers | |

| How to capture registry information from an OPC Server so that it can be registered in Windows on another machine. | Watch Video |

To find out more information on the Exaquantum Data Historian, please visit our corporate site.