Process safety is a disciplined framework for managing the integrity of systems and processes. Its purpose is to reduce risk and to ensure that process plants are operating within tolerable limits for humans, environment, assets and production continuity.

It requires significant investment, in that many smart subject matter experts come together to analyse risk and design safety systems with very complicated math to ensure the ongoing risk at a plant is deemed tolerable. Assumptions are made to optimize solutions based on process.

It requires significant investment, in that many smart subject matter experts come together to analyse risk and design safety systems with very complicated math to ensure the ongoing risk at a plant is deemed tolerable. Assumptions are made to optimize solutions based on process.

The challenge becomes determining if my real-time operating data supports the analysis, design, and assumptions used up front. What happens when something changes? What happens when any of the initial assumptions just aren’t accurate ? What happens when there is new risk that is not consider initially that occurs during plant operation?

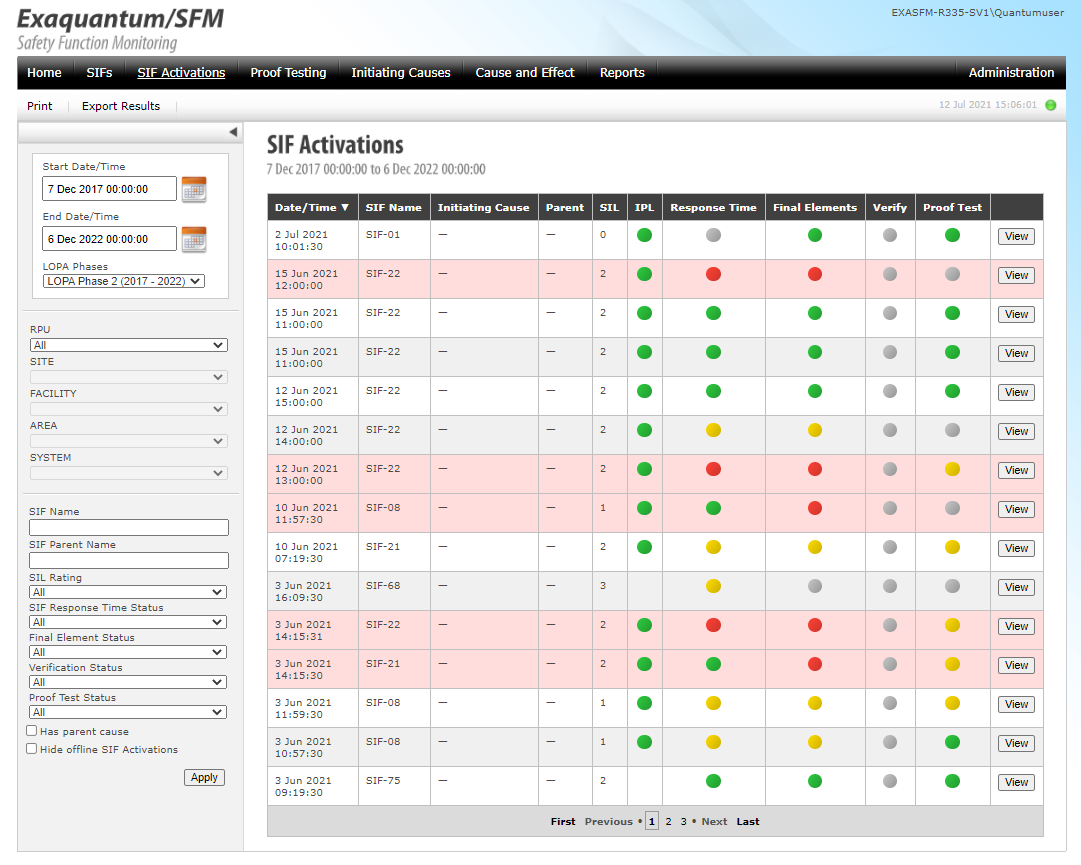

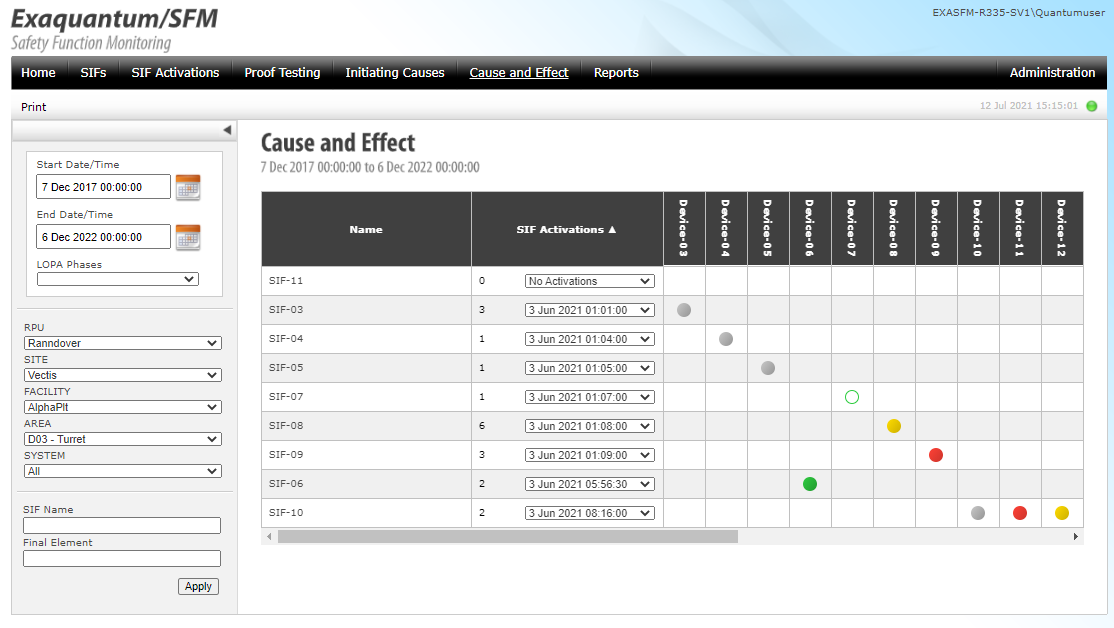

Yokogawa’s Safety Function Monitoring (SFM) quickly identifies assumptions that fail to meet design targets, pinpoints the additional risk that was previously invisible, and empowers you to take action to eliminate risk from the business. It also facilitate the recording of new risk during plant operation.

SFM is the final piece within the lifecycle that protects your investment by keeping your risk profile aligned with what good looks like as defined by the subject matter experts.

Benefits of Exaquantum/SFM R3.50, released June 2024

Improve safety

To provide the data and tools necessary to improve the safety design philosophy or make changes to the safety philosophy throughout the plant lifecycle.

Streamline safety compliance

To automatically collect and present safety performance information via a single access point that reduces manual overheads and errors, which simplifies compliance to safety standards.

Optimise Safety Instrumented Systems (SIS) costs

To optimise OPEX costs of maintaining safety excellence; an over-engineered SIS may exceed safety requirements but not be cost-effective, similarly an under engineered SIS maybe cost effective but may compromise safety.

Reduce operational risk

To validate the assumption made during the design phase and collection of new risk during operation.

Safety Management overview video

Safety Function Monitoring Brochure

Exaquantum Safety Function Monitoring (SFM) software provides continuous monitoring and evaluation of operational safety data to highlight deviations or deficiencies in safety system design and optimize performance.

Monitoring & Improving Safety Performance

Download our article to find out how software solutions help manage and oversee the operational safety performance of process plants.

Safety Management Solutions

To find out more about our Safety Management solutions, please visit our corporate site.